Wildout’s Motor Build-Up with nuff pics, you've been warned

#1

So I finally had enough time to write up a progress thread of my engine build up. The whole reason why I ended up having to rebuild the motor this year was because of a burnt 4th cylinder exhaust valve, so I decided I might as well fix all the problems now while I had the time…i.e. valve seals and oil control rings.

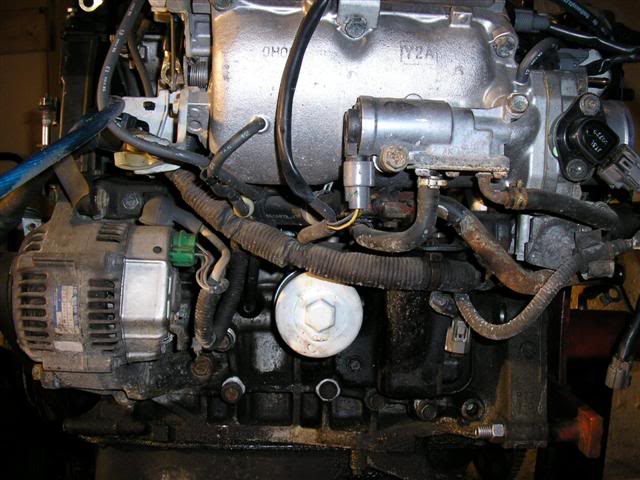

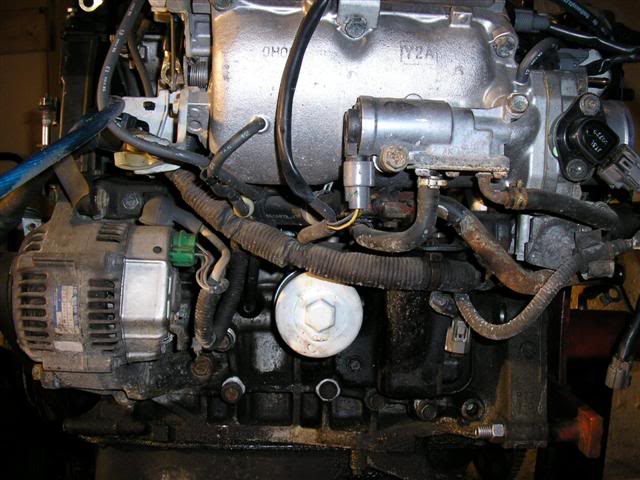

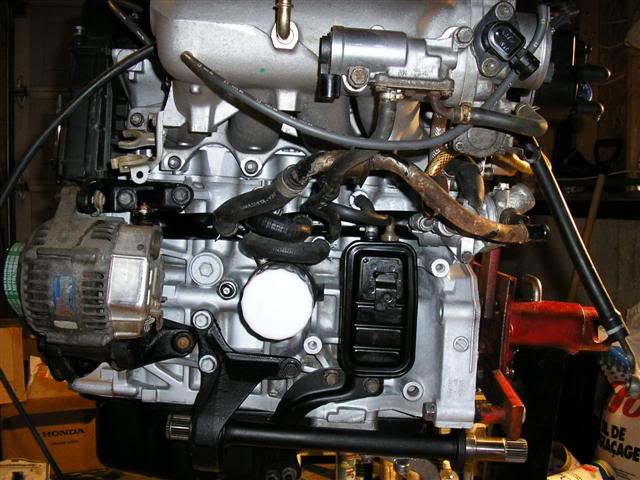

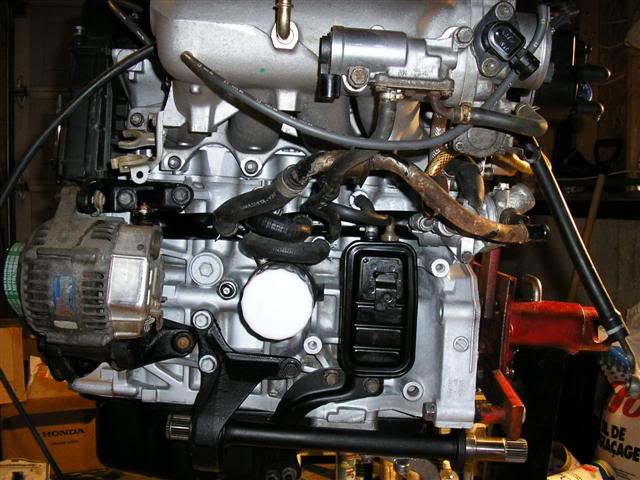

So it begins, with what my motor looked like just after pulling it from the engine bay.

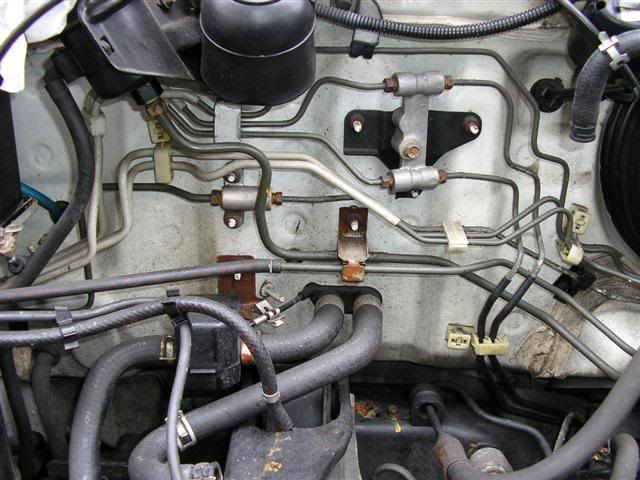

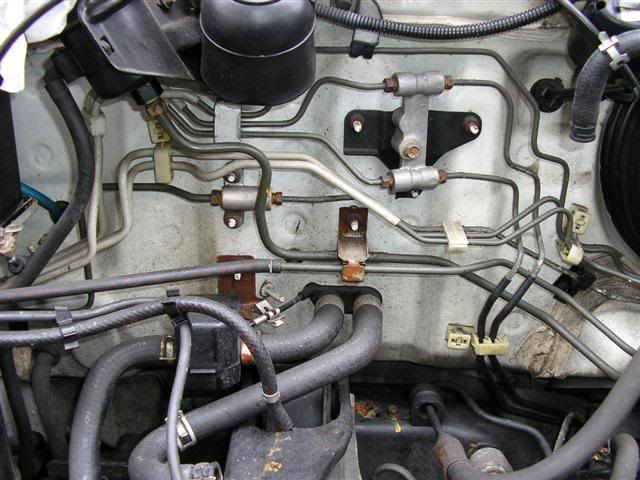

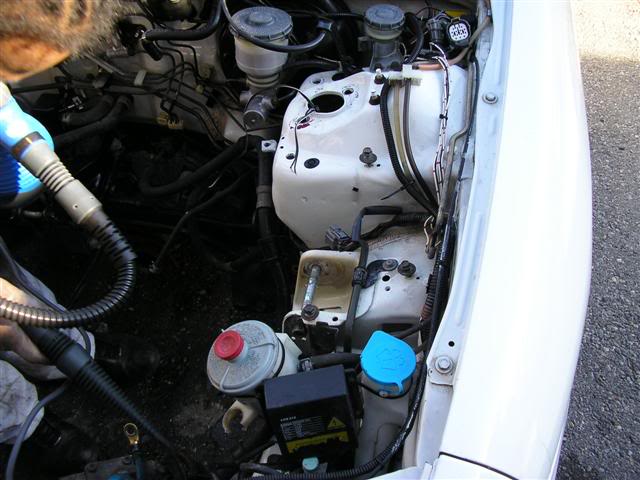

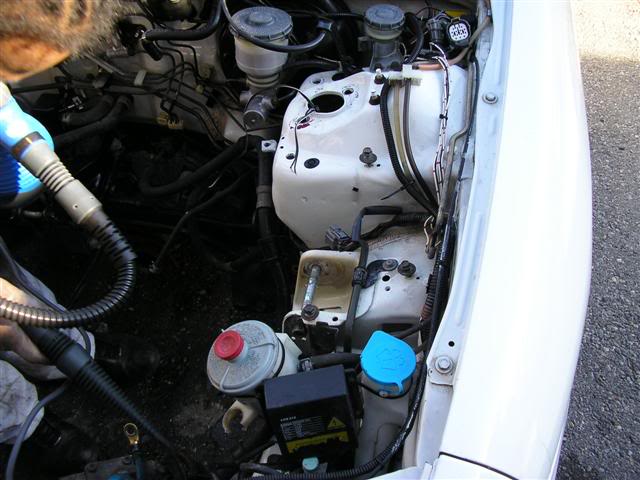

How the engine bay looked, dirty as ----, with wires everywhere

Random pics of the dirty engine

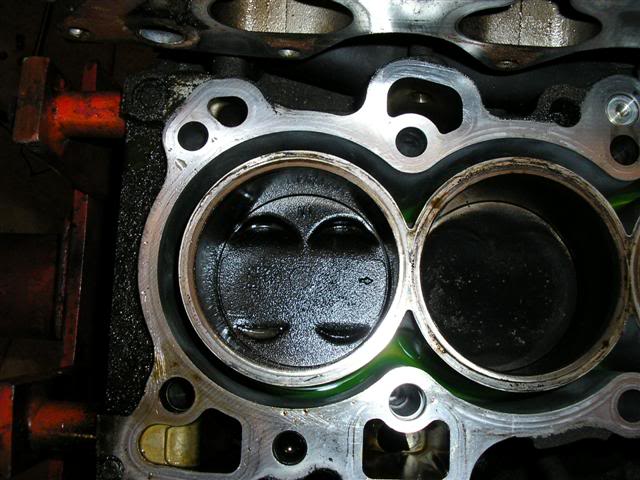

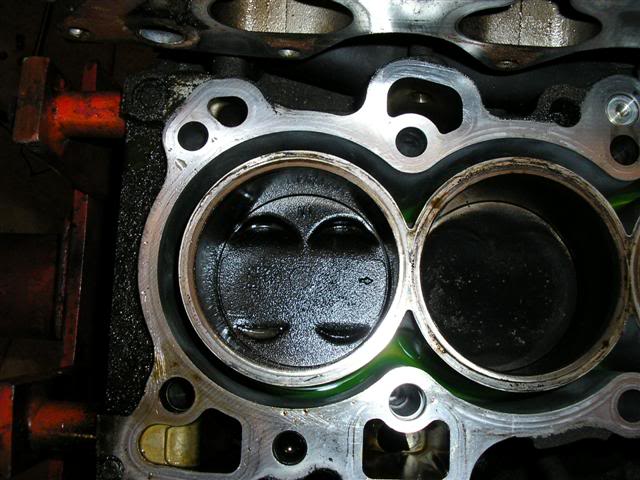

With the head off

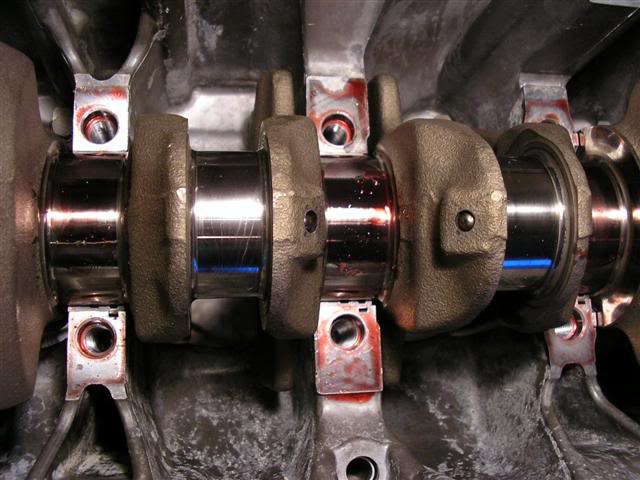

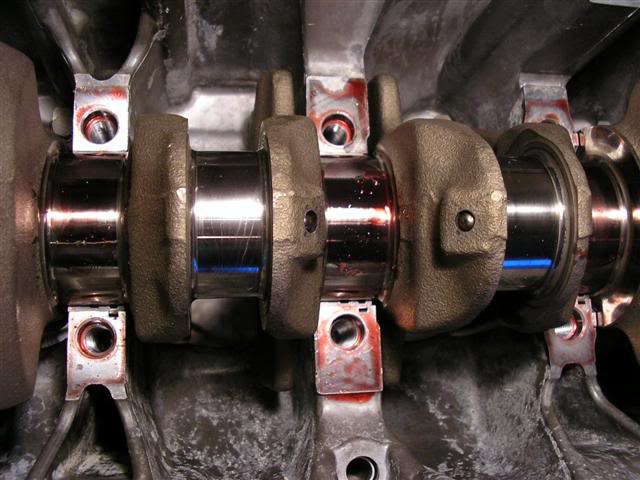

The crankshaft, bearings, girdle, main cap, oil pickup and windage tray

The almost bare block

How my garage looked after removing everything off the block and head, then putting them in label sandwich bags

What kept my battery charged the whole time while building my engine

So it begins, with what my motor looked like just after pulling it from the engine bay.

How the engine bay looked, dirty as ----, with wires everywhere

Random pics of the dirty engine

With the head off

The crankshaft, bearings, girdle, main cap, oil pickup and windage tray

The almost bare block

How my garage looked after removing everything off the block and head, then putting them in label sandwich bags

What kept my battery charged the whole time while building my engine

Last edited by WildoutWhiteGSR; 04-23-2006 at 06:42 PM.

#2

The other parts I took off the car for the time being.

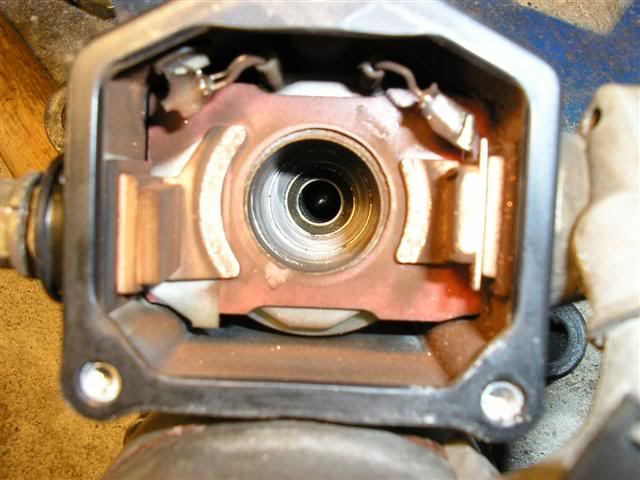

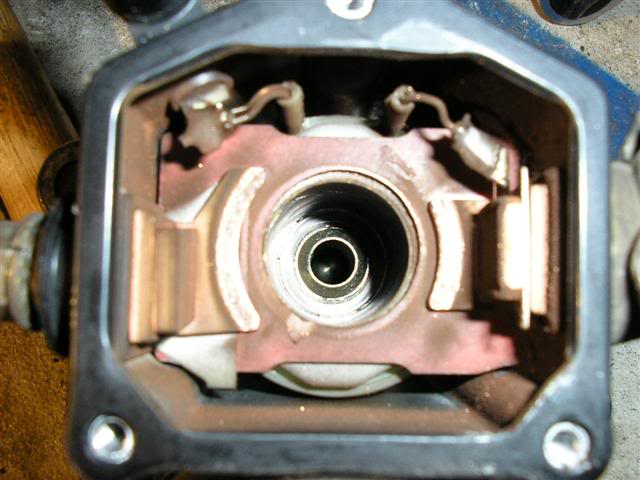

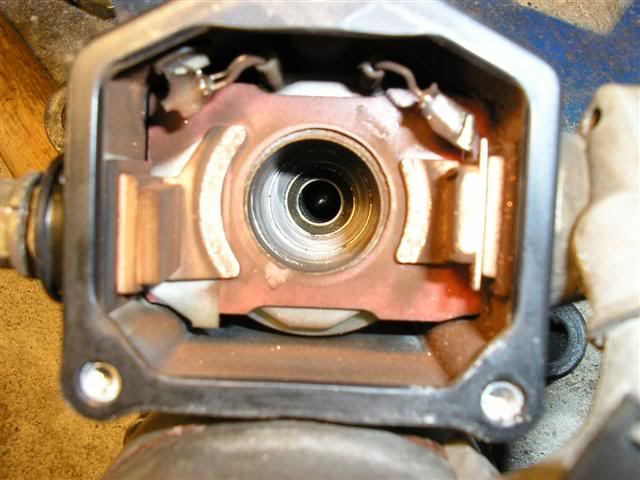

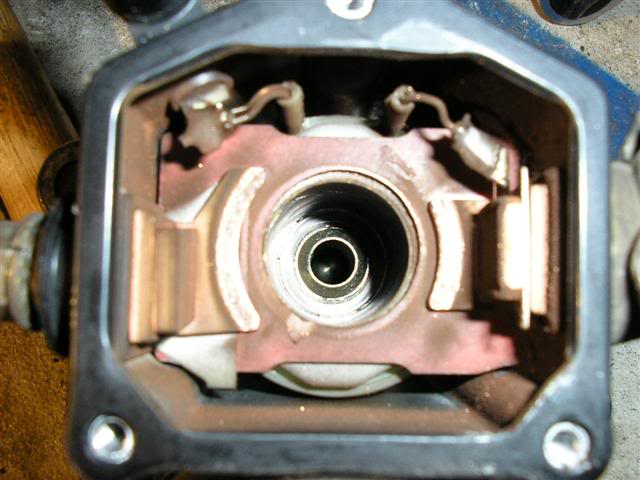

The starter opened up

The old driveshafts and intermediate shaft

The knuckles and upper control arms

The brake caliper brackets, rotors, lower forks and my Hayame full coilover suspension

The clutch and flywheel

Now onto the progress pictures

I took the block to my backyard and got some engine degreaser and brake cleaner to clean it up. Then rinse it off with some high pressure water.

How it looked after I finished cleaning it up and done drying

Notice the rusty looking cylinders; it was just surface rust, so I wasn’t worried at all. It came off by just wiping it with your finger. I was also boring .25 over so nothing the machine shop can’t get rid of.

Now onto the most time consuming and looked over parts of building a motor; cleaning up the threads of the head studs and main studs holes.

First got to make sure you buy the right sized tap. In my case it was 11mm x 1.5mm. Confirmed by the Helms manual and checking the old head bolts and main bolts that came out of the block.

More proof, the head bolt screws into the main bolt hole perfectly. All the confirmation I need.

The starter opened up

The old driveshafts and intermediate shaft

The knuckles and upper control arms

The brake caliper brackets, rotors, lower forks and my Hayame full coilover suspension

The clutch and flywheel

Now onto the progress pictures

I took the block to my backyard and got some engine degreaser and brake cleaner to clean it up. Then rinse it off with some high pressure water.

How it looked after I finished cleaning it up and done drying

Notice the rusty looking cylinders; it was just surface rust, so I wasn’t worried at all. It came off by just wiping it with your finger. I was also boring .25 over so nothing the machine shop can’t get rid of.

Now onto the most time consuming and looked over parts of building a motor; cleaning up the threads of the head studs and main studs holes.

First got to make sure you buy the right sized tap. In my case it was 11mm x 1.5mm. Confirmed by the Helms manual and checking the old head bolts and main bolts that came out of the block.

More proof, the head bolt screws into the main bolt hole perfectly. All the confirmation I need.

#3

Chasing the threads of the head bolts hole

The shavings that came out of all the 10 head studs holes (sorry for the blurry pictures)

Onto the main bolt holes, it’s the same process

The results, this is what came out of each main bolt hole. Shocking isn’t it

How the threads looked after, nice and clean

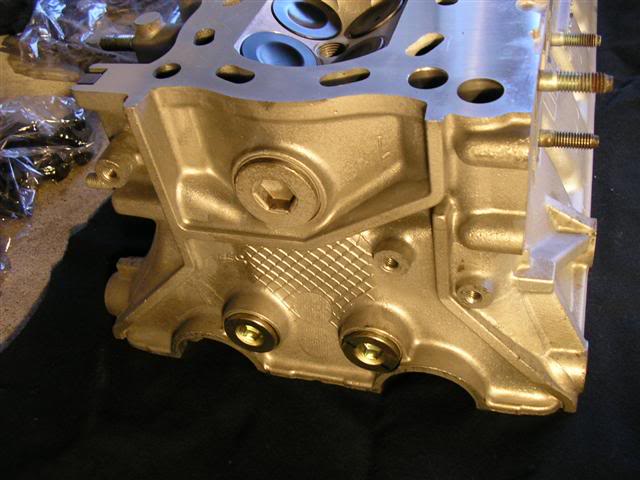

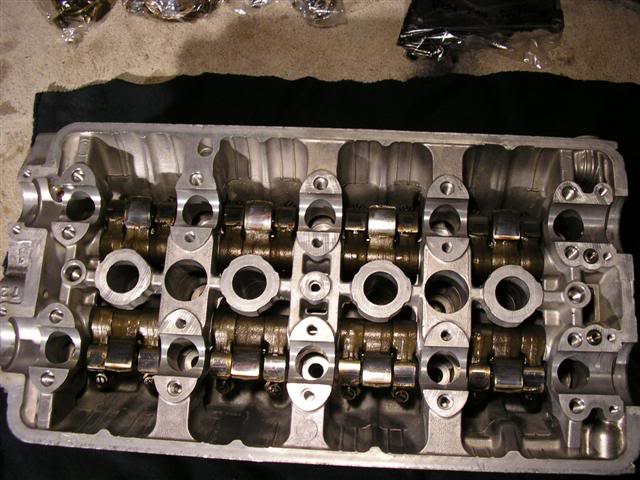

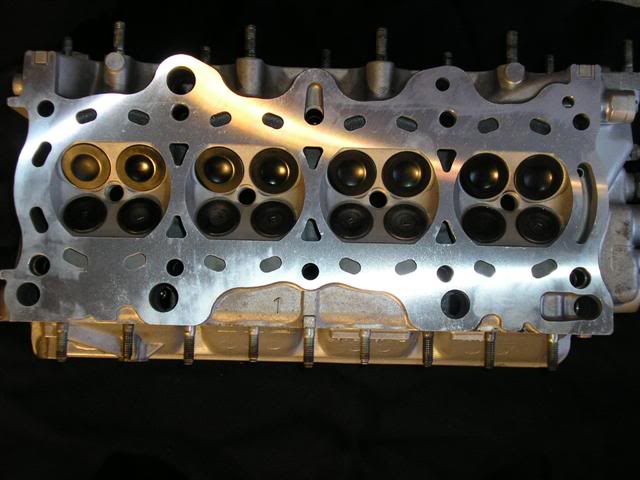

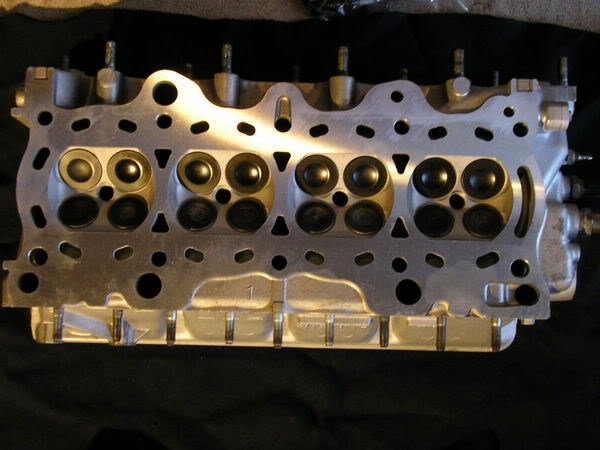

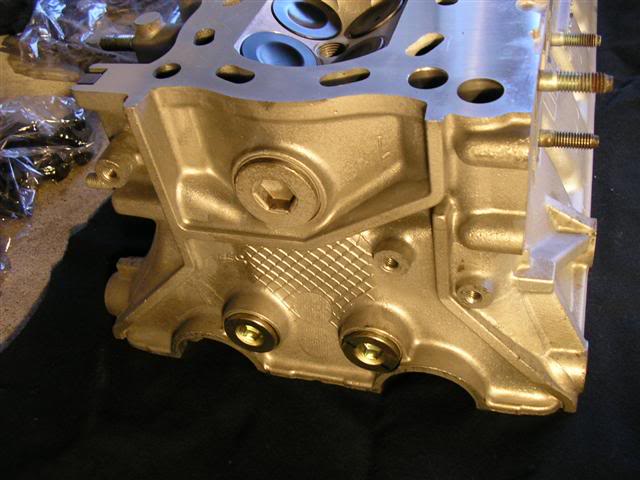

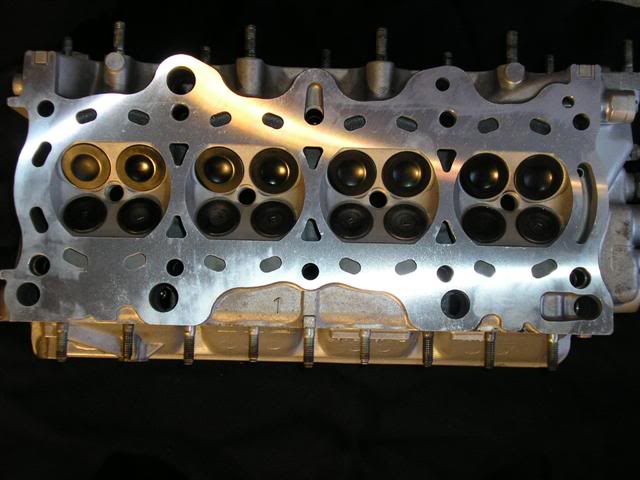

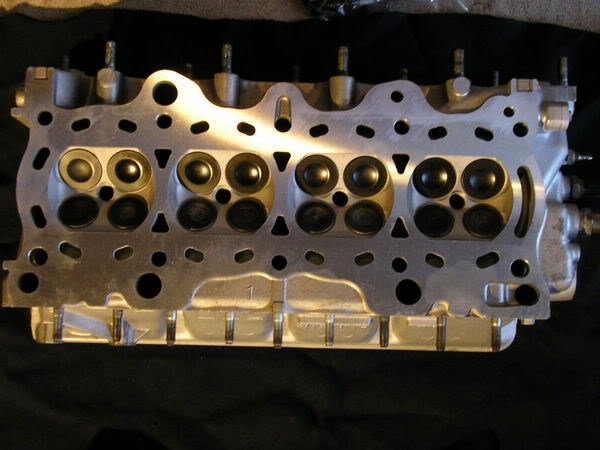

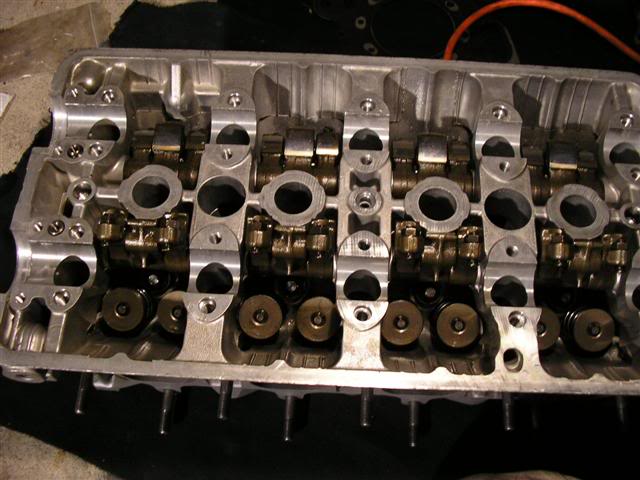

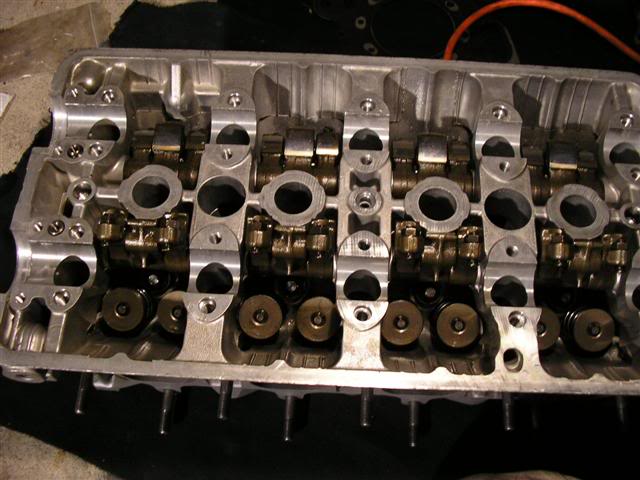

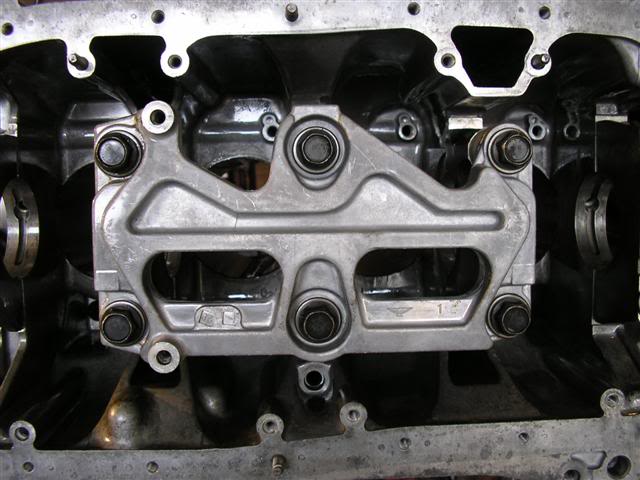

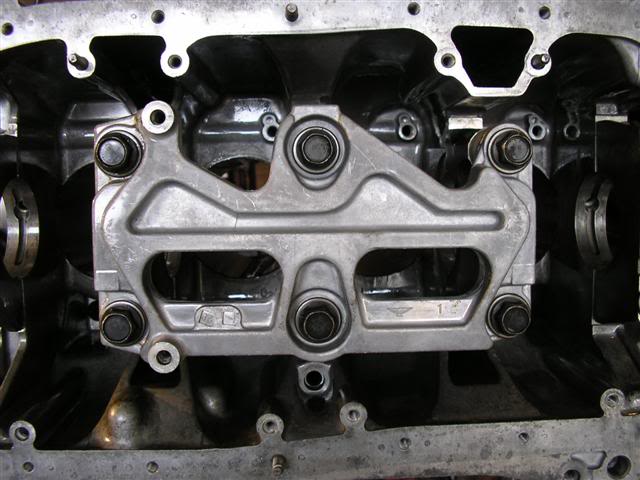

In the meantime the head was sent out to my local machine shop and this is how it looked when I got it back

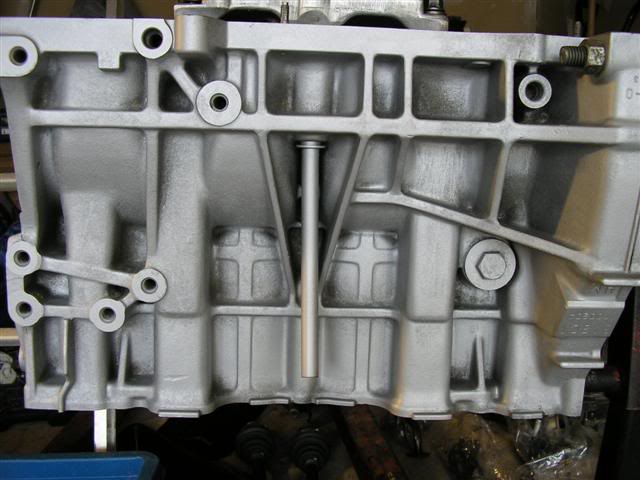

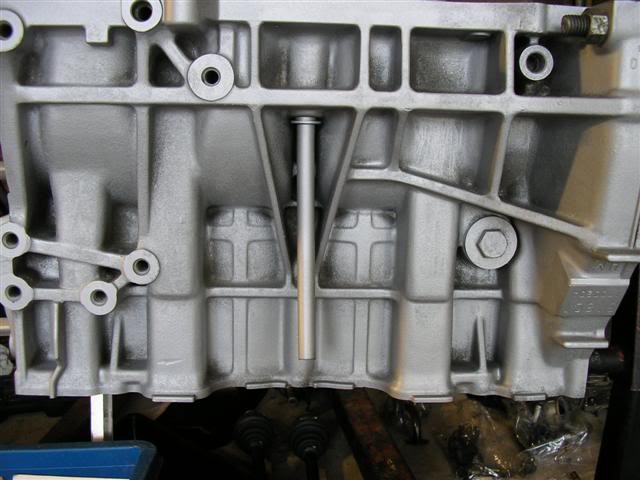

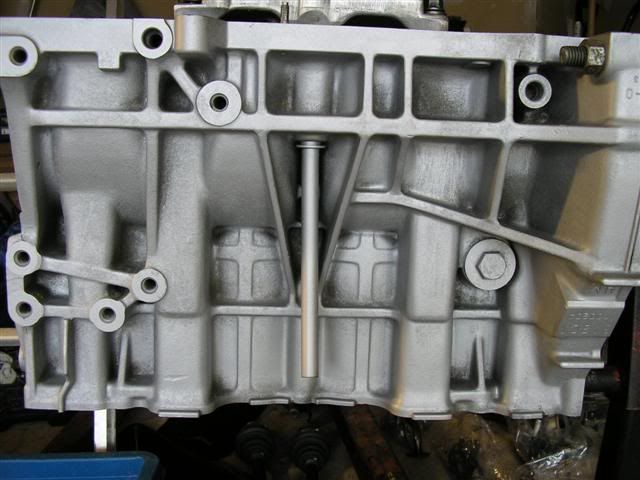

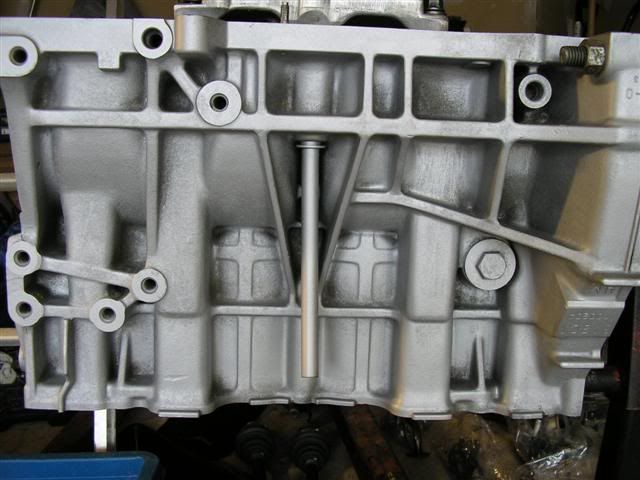

Next the block was sent off and this is how I received it back from the machine shop

The heads done for now until I put it on the block.

The parts I ordered have arrived, sweet.

My replacement distributor king dizzy. My old one was on its way out. Gotta love 3 year warranties.

My injectors before

My injectors balanced and cleaned.

My new jdm itr pistons along with wrist pins and new OEM piston rings

My parts box

The shavings that came out of all the 10 head studs holes (sorry for the blurry pictures)

Onto the main bolt holes, it’s the same process

The results, this is what came out of each main bolt hole. Shocking isn’t it

How the threads looked after, nice and clean

In the meantime the head was sent out to my local machine shop and this is how it looked when I got it back

Next the block was sent off and this is how I received it back from the machine shop

The heads done for now until I put it on the block.

The parts I ordered have arrived, sweet.

My replacement distributor king dizzy. My old one was on its way out. Gotta love 3 year warranties.

My injectors before

My injectors balanced and cleaned.

My new jdm itr pistons along with wrist pins and new OEM piston rings

My parts box

#4

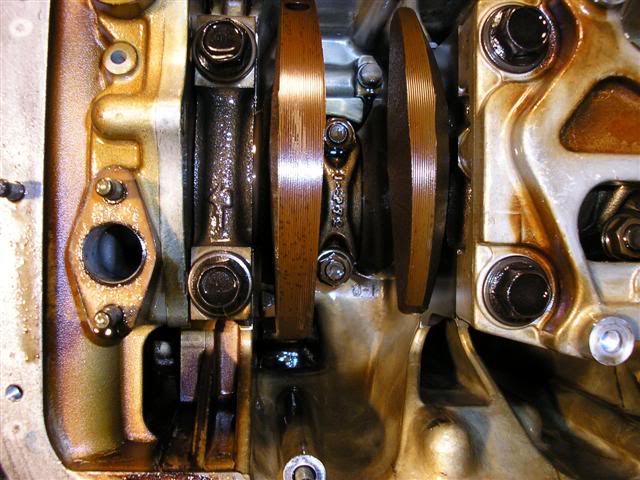

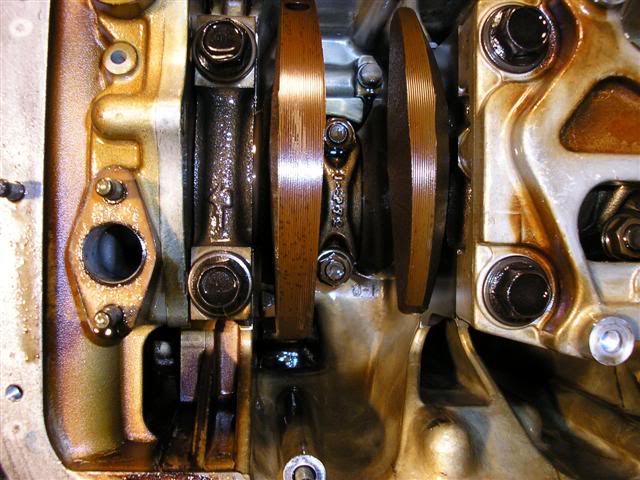

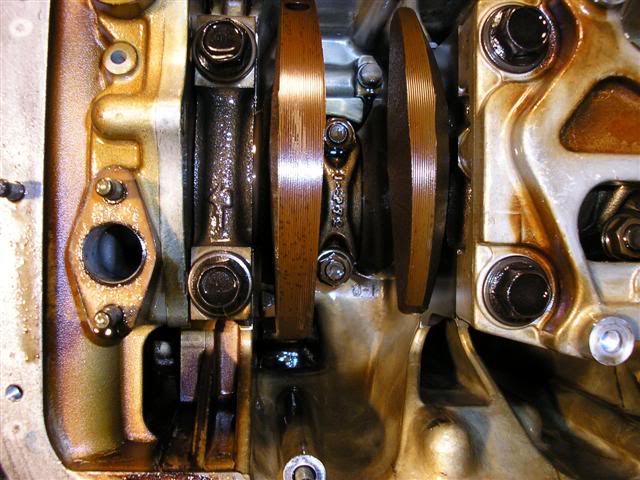

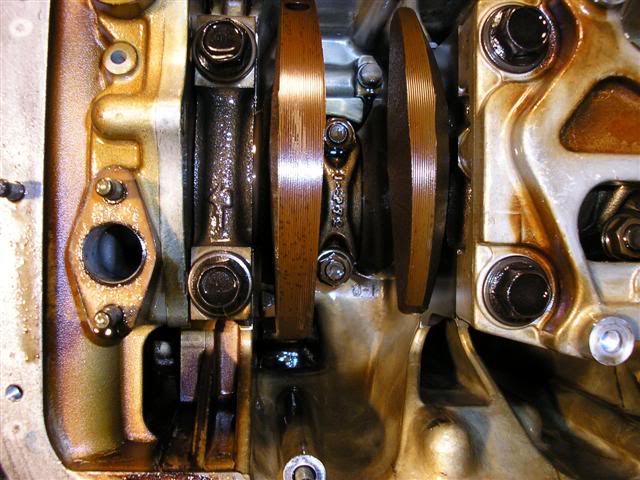

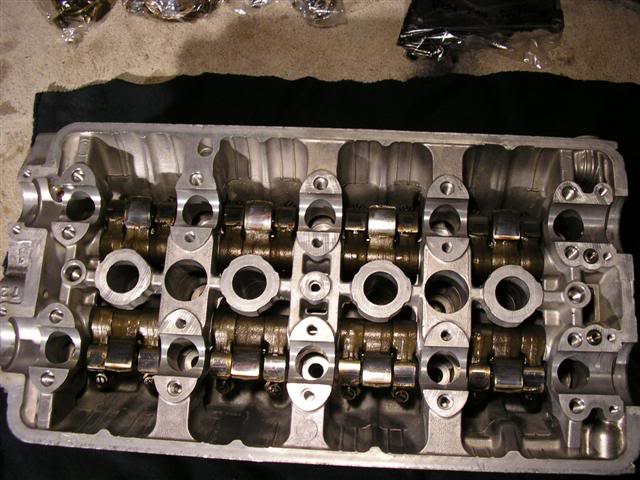

Next I started to re-assemble the head. Intake outer, intake inner and exhaust outer valve springs, along with valve spring seats and retainers. Intake is the top two springs and the exhaust is the bottom springs. Exhaust valve springs are slightly taller than the intake valve spring for the GSR.

Exhaust valve springs in the back, intake outer up front

Intake valves on the left and exhaust on the right. My burnt 4th cylinder exhaust valve in the middle

The valve keepers a.k.a. ping -----it!

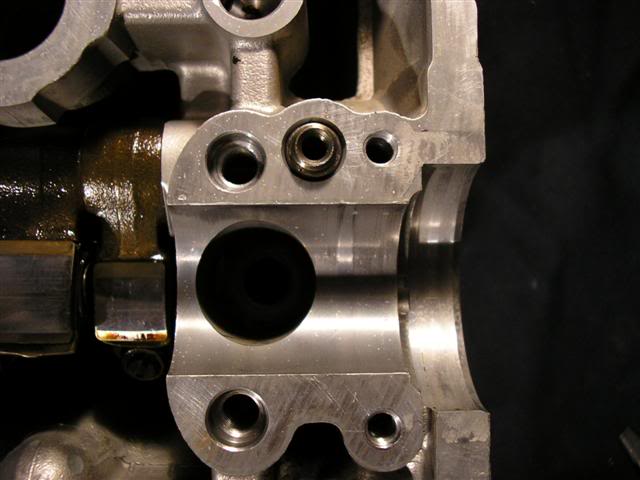

It’s the same for the exhaust side. Then I made sure that the intake and exhaust oil orifice was in place.

Then next I replaced all the studs on the intake side of the head to accommodate the thicker Hondata intake gasket

I made a bracket for the EVAP Purge Solenoid and connected the rest of the little things

I also replaced the studs that connect the throttle body to the intake manifold.

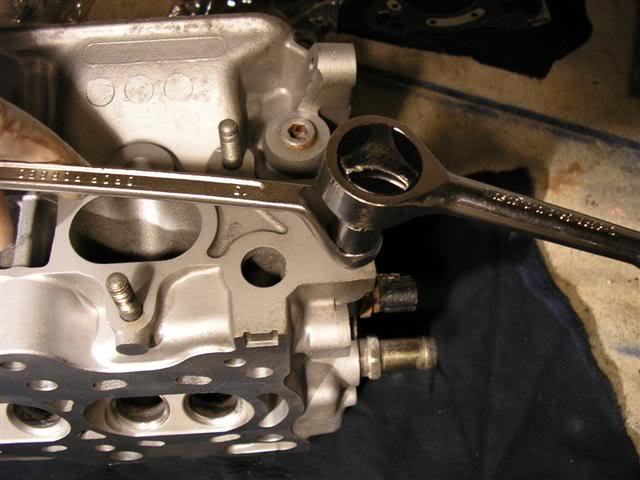

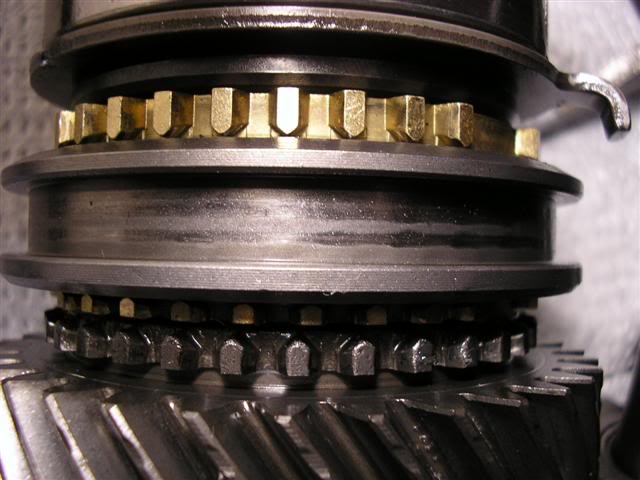

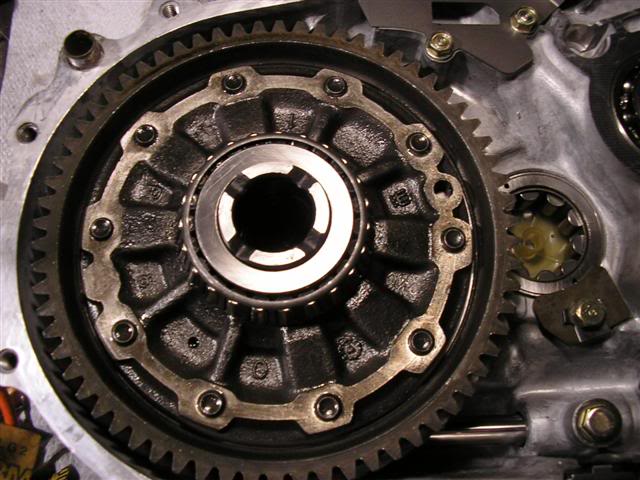

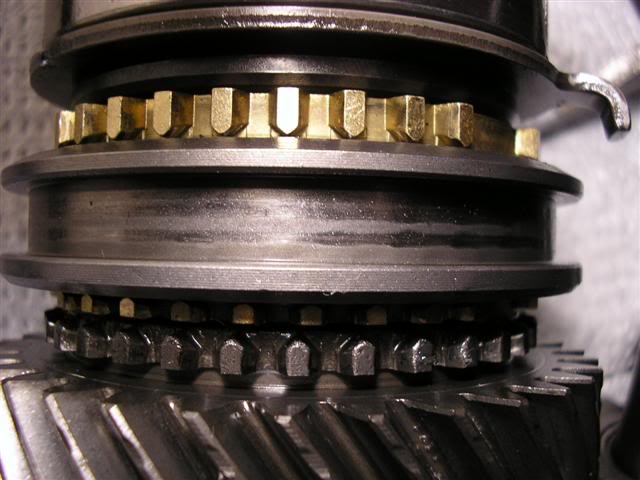

Next I took the transmission apart and cleaned all the gears and transmission magnet. I also inspected the syncro’s, gears and gear sleeves

After all that work, it was time to work on putting the block back together.

****will finish the rest of the progress write up with pics a little later on****

Exhaust valve springs in the back, intake outer up front

Intake valves on the left and exhaust on the right. My burnt 4th cylinder exhaust valve in the middle

The valve keepers a.k.a. ping -----it!

It’s the same for the exhaust side. Then I made sure that the intake and exhaust oil orifice was in place.

Then next I replaced all the studs on the intake side of the head to accommodate the thicker Hondata intake gasket

I made a bracket for the EVAP Purge Solenoid and connected the rest of the little things

I also replaced the studs that connect the throttle body to the intake manifold.

Next I took the transmission apart and cleaned all the gears and transmission magnet. I also inspected the syncro’s, gears and gear sleeves

After all that work, it was time to work on putting the block back together.

****will finish the rest of the progress write up with pics a little later on****

#5

damnnnnnnnn T thats some serious work you put in. Glad to see you took pics to show what it was to what it will become. Nuff respects for the effort and patient you have to do that. Can't wait to see how it runs, good work T!

#9

Wayne for a couple of reasons

-price

-mine are still good, except one

-I'm going to use that money for valvesprings instead

-and you can use prelude vtec lma's which are basically the same as the itr's except that they're $180 cheaper

I'll be replacing them anyways when I get cams

-price

-mine are still good, except one

-I'm going to use that money for valvesprings instead

-and you can use prelude vtec lma's which are basically the same as the itr's except that they're $180 cheaper

I'll be replacing them anyways when I get cams

#11

There's plenty to do outside my room but I choose not to!

Join Date: Sep 2003

Location: Somewhere

Posts: 5,183

Ok guys...here's the truth...I did all the work and Trenell only took pics...

but honestly...you guys have NO idea how much time went into this...I think Trenell knew the Helms manual WAY better than any school textbook! We're all very proud of him...

(hides and runs for being girly...:*****: )

but honestly...you guys have NO idea how much time went into this...I think Trenell knew the Helms manual WAY better than any school textbook! We're all very proud of him...

(hides and runs for being girly...:*****: )

#17

Thanks guys, I'm still not done just yet.

Omar in total with tools, parts, shipping, brokerage, machine work and tax roughly $2200

Lou at the time I couldn't find any LSD's or JDM 4.785 or ATS 4.9 FD what-so-ever, now that it's back together they're popping up all over.

Figures eh

Omar in total with tools, parts, shipping, brokerage, machine work and tax roughly $2200

Lou at the time I couldn't find any LSD's or JDM 4.785 or ATS 4.9 FD what-so-ever, now that it's back together they're popping up all over.

Figures eh

#18

Originally Posted by WildoutWhiteGSR

Lou at the time I couldn't find any LSD's or JDM 4.785 or ATS 4.9 FD what-so-ever, now that it's back together they're popping up all over.

Figures eh

Figures eh

#22

Sorry Lou no OBX for me, thanks though. If you have a JDM final drive I'll gladly buy it

Mark and Scott the machine work was done by Canadian Cylinder Head in North York

Mark and Scott the machine work was done by Canadian Cylinder Head in North York

Last edited by WildoutWhiteGSR; 04-24-2006 at 10:58 AM.

#25

#31

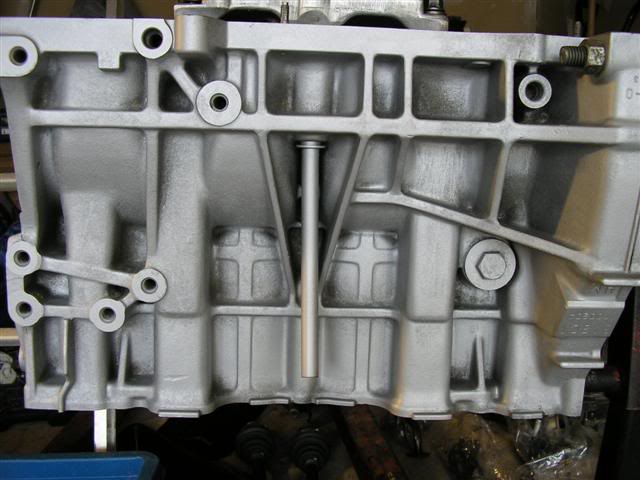

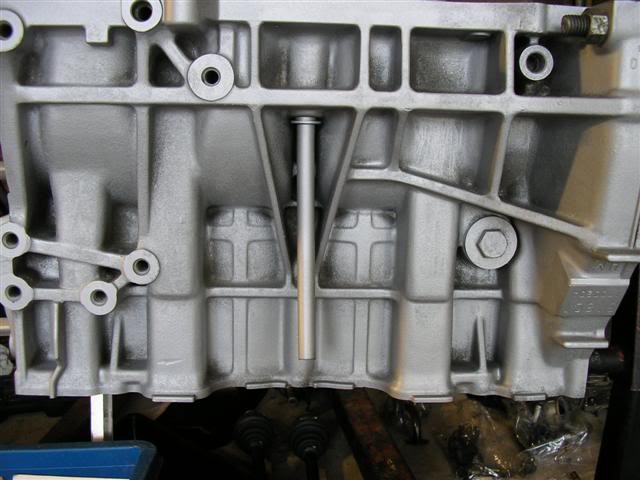

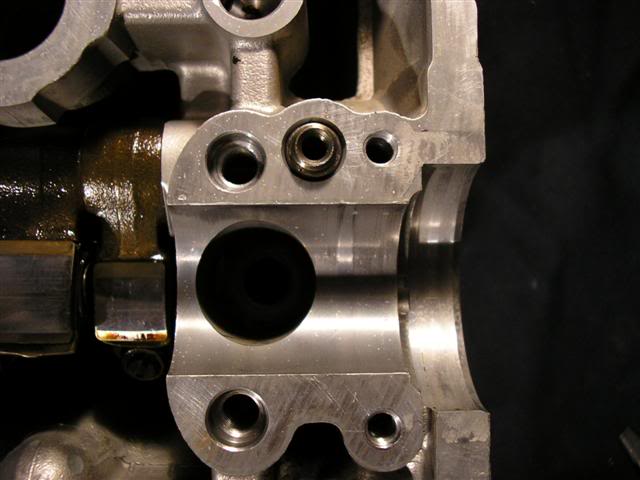

Time to put the block back together. How it looked when I got it from the machine shop along with the serviced oil pump and new rear main seal

Installing the oil squirters

Cleaning up the main bores and bearings for plasitgauging

Bearings

Installed in the mains

Bearings lubed up in preparation of the cleaned up and micropolished crank

Thrust washers are next

Installed

Crankshaft in place

Plastigauging in process

After I finished plastigauging all the mains, they were cleaned up of any excess plastigauge and then lubed thoroughly with engine assembly lube as well as the girdle

Since I had the machine shop install the new pistons on the connecting rods for me, along with installing the piston rings and checking there gap, its one step closer to final assembly. Here they are

Cleaned up the surfaces in preparation of the bearings

Then I needed to remove the cap to install the bearings

Now time to clean up the cylinders for the piston and rod assembly

Then lube up the cylinder walls with WD40

Piston ring compressor

Wiping WD40 on the piston ring compressor

Time to install the pistons, ensuring that all the piston rings are facing up and that the gaps are properly orientated

All installed

Then made sure to use the ARP assemble lube on the nuts and thread bolt end, to have the correct torque for the plastigauging. If you look carefully, you can see the plastigauge in the background

Rod cap on

Lubed up nut

Placed on the rod

Me torquing down the rod bolts to ARP specs

The best way I found to loosen the cap after plastigauging.

Installing the oil squirters

Cleaning up the main bores and bearings for plasitgauging

Bearings

Installed in the mains

Bearings lubed up in preparation of the cleaned up and micropolished crank

Thrust washers are next

Installed

Crankshaft in place

Plastigauging in process

After I finished plastigauging all the mains, they were cleaned up of any excess plastigauge and then lubed thoroughly with engine assembly lube as well as the girdle

Since I had the machine shop install the new pistons on the connecting rods for me, along with installing the piston rings and checking there gap, its one step closer to final assembly. Here they are

Cleaned up the surfaces in preparation of the bearings

Then I needed to remove the cap to install the bearings

Now time to clean up the cylinders for the piston and rod assembly

Then lube up the cylinder walls with WD40

Piston ring compressor

Wiping WD40 on the piston ring compressor

Time to install the pistons, ensuring that all the piston rings are facing up and that the gaps are properly orientated

All installed

Then made sure to use the ARP assemble lube on the nuts and thread bolt end, to have the correct torque for the plastigauging. If you look carefully, you can see the plastigauge in the background

Rod cap on

Lubed up nut

Placed on the rod

Me torquing down the rod bolts to ARP specs

The best way I found to loosen the cap after plastigauging.

#32

This is after I had got the cap loose

After finishing all the plastigauging for all the rods, I made sure to apply enough engine assembly lube to the journals

Connecting rod end play within stock specs

Finally I can move on to the rest of the engine block assembly. It took me about 3 hours to plastigauge all the bearings. Done twice, some three times for accuracy.

How the pistons should look within there respective cylinders now that they are torqued down properly

Now for the pictures of the other little/random things that go onto the block

Now I move onto the oil pump, I prep the surface by cleaning it up then placing the high temp sealant around the matting surface.

***forgot to take a picture of that, my bad***

Oil Pump Installed along with a new oil pickup gasket

Oil pickup cleaned along with the bolts & nuts

The same treatment is applied to the rear main seal

Rear main seal installed along with the new oil pan gasket and windage tray

Oil Pickup Installed

Oil Pan installed along with my magnetic Spoon drain bolt

Onto the golden eagle head studs

Gotta replace that o-ring on the oil orifice

Oil Orifice installed

Next it’s time for the headgasket, only OEM for me

Yup it’s facing the right way

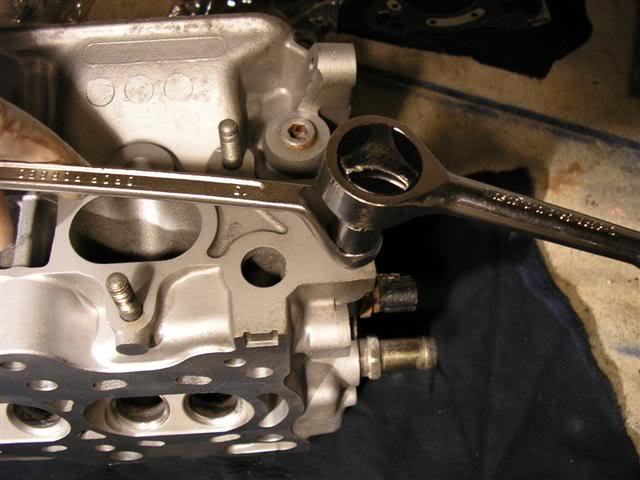

Time to put on the head

Don’t forget those dowel pins

Me lubing the ---- out of the washers and nuts

Head installed

Time for the cams, lube up the cam journals

Same goes for the cams

Installed the cam holders along with the cam holder plates (note the bolts to hold on the valve cover are on wrong, should be on the inner holes)

Valve cover put on

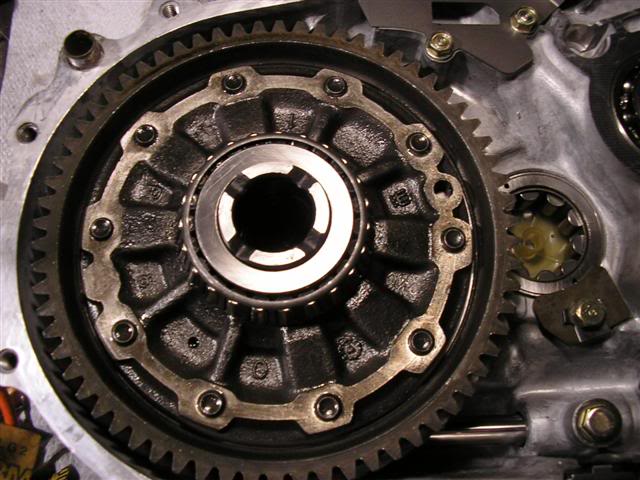

Flywheel Installed

Pressure Plate and Clutch Disk Installed

Putting the transmission back on the block by myself and trying to take the picture at the same time

Practically done pictures

Other things I did while the engine was out

You didn’t think that I would leave the engine bay that dirty did you?

Picture in engine bay

***will put up when I get home from work***

After finishing all the plastigauging for all the rods, I made sure to apply enough engine assembly lube to the journals

Connecting rod end play within stock specs

Finally I can move on to the rest of the engine block assembly. It took me about 3 hours to plastigauge all the bearings. Done twice, some three times for accuracy.

How the pistons should look within there respective cylinders now that they are torqued down properly

Now for the pictures of the other little/random things that go onto the block

Now I move onto the oil pump, I prep the surface by cleaning it up then placing the high temp sealant around the matting surface.

***forgot to take a picture of that, my bad***

Oil Pump Installed along with a new oil pickup gasket

Oil pickup cleaned along with the bolts & nuts

The same treatment is applied to the rear main seal

Rear main seal installed along with the new oil pan gasket and windage tray

Oil Pickup Installed

Oil Pan installed along with my magnetic Spoon drain bolt

Onto the golden eagle head studs

Gotta replace that o-ring on the oil orifice

Oil Orifice installed

Next it’s time for the headgasket, only OEM for me

Yup it’s facing the right way

Time to put on the head

Don’t forget those dowel pins

Me lubing the ---- out of the washers and nuts

Head installed

Time for the cams, lube up the cam journals

Same goes for the cams

Installed the cam holders along with the cam holder plates (note the bolts to hold on the valve cover are on wrong, should be on the inner holes)

Valve cover put on

Flywheel Installed

Pressure Plate and Clutch Disk Installed

Putting the transmission back on the block by myself and trying to take the picture at the same time

Practically done pictures

Other things I did while the engine was out

You didn’t think that I would leave the engine bay that dirty did you?

Picture in engine bay

***will put up when I get home from work***

Last edited by WildoutWhiteGSR; 04-26-2006 at 12:19 PM.

#33

crazy work trenell!!! me and my boy just put on a new fender, and replaced his door and internals, and we felt like the biggest mechanics, and i come home to read this thread...ahaha...

question? did you learn how to do all this work by yourself? helms? internet?

and when you said : "

You didn’t think that I would leave the engine bay that dirty did you?"

i thought we were gonna see some wire tucking pics!!!

but great work nonetheless, and motivates the hell out of me to become more engine savvy!!!

question? did you learn how to do all this work by yourself? helms? internet?

and when you said : "

You didn’t think that I would leave the engine bay that dirty did you?"

i thought we were gonna see some wire tucking pics!!!

but great work nonetheless, and motivates the hell out of me to become more engine savvy!!!

#34

Originally Posted by esguerra

question? did you learn how to do all this work by yourself? helms? internet?

Originally Posted by esguerra

and when you said : "

You didn’t think that I would leave the engine bay that dirty did you?"

i thought we were gonna see some wire tucking pics!!!

You didn’t think that I would leave the engine bay that dirty did you?"

i thought we were gonna see some wire tucking pics!!!

-so far fuel rail is done

-vtec solenoid

-distributor

-driver side near the shock tower

and some of the main harness near the battery. Those were the only ones I could move without cutting and extending wires, since I didn't want to do it and have electrical problems later on causing Nick not to be able to tune my car. Now that it's up and running, I'll finish it up once I stop being so lazy

#37

Originally Posted by esguerra

oh, woops...well great job...you and fuzz, all motor twins of 2006!

Last edited by WildoutWhiteGSR; 04-26-2006 at 06:44 PM.